Filler Masterbatches

Filler masterbatch is a specialized formulation composed of high-quality additives, mineral fillers, and carrier resins. It is widely used in the plastics industry to enhance mechanical properties, improve processability, and reduce raw material costs without compromising product quality. These masterbatches are carefully engineered to provide optimal dispersion and compatibility with various polymer systems.Arvinda Minerals offers high-quality filler masterbatches tailored to meet the specific needs of different industries, ensuring performance, durability and cost savings.

Opacity & Surface Finish

Provides better opacity and a smooth surface finish, making it ideal for applications that require a polished appearance

Economical

Filler masterbatch helps reduce the overall cost of plastic production by replacing a portion of expensive virgin polymers with cost-effective fillers

Mechanical Properties

Enhances tensile strength, stiffness, and durability, making plastic products more robust and long-lasting

Better Processing

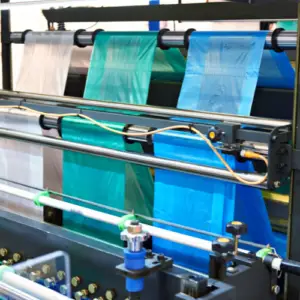

Improves extrusion, injection molding, and blow molding processes by enhancing flow properties and reducing cycle times

Range of Filler Masterbaches

AFAB Calcium Carbonate Filler

AFAB Calcium Carbonate filler masterbatch enhances product performance by reducing shrinkage and improving surface properties, widely used in PP tape extrusion, injection molding, blow molding, PE film, PS thermoforming, clear film, PP compounding & lamination

AFAB Talc Filler

Arvinda Mineral’s talc-based masterbatche are formulated using high-purity talc, free from asbestos and crystalline silica, making them ideal for compounding, PP sheet extrusion, PET extrusion, transparent films, and PS sheet extrusion

These Filler Masterbatches can be used in:

Industry