emiSEAL

High Emissivity Ceramic Coating

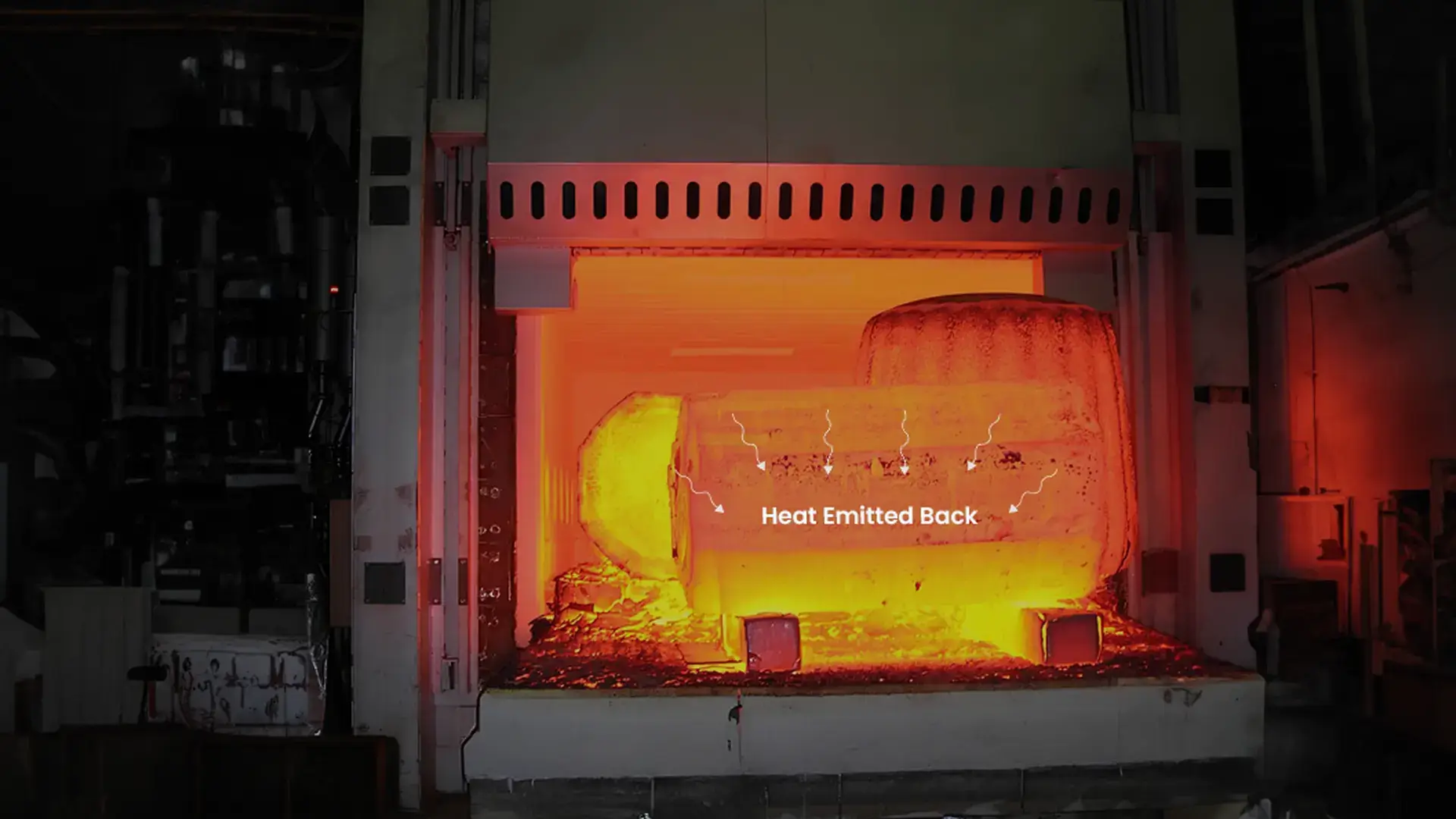

emiSeal is a high-emissivity ceramic coating which radiates heat incident on refractory walls of furnaces back onto the load in the furnace. The coating enhances the thermal efficiency of the furnace, resulting in fuel savings. emiSeal is engineered to protect refractory linings in extremely high-temperature environments, up to 1200°C., this inorganic binder-based coating system ensures both longevity and thermal efficiency. emiSeal lowers the residual heat in the refractory walls and results in reducing thermal shock. This significantly enhances the performance and durability of refractory linings and helps reduce downtime.

Heat stability upto 1200°C

Designed to endure extreme temperatures, ensuring reliability in high-heat environments

Emits heat back

Enhances thermal efficiency by reflecting and radiating heat away from the surface

Long-lasting protection

Provides a durable barrier against thermal degradation, oxidation, and wear

Uniform heat distribution

Minimizes thermal stress by evenly dispersing heat across the coated surface

energy conservation

Reduces energy consumption by optimizing heat management and efficiency

emiSEAL can be applied on :